A Day in the STEINBILD Manufactory: The Fascinating Creation of a STEINBILD

16.05.2023 | INSIGHTS

Immerse Yourself in the World of STEINBILD and Experience Firsthand How We Transform the Unparalleled Beauty of Natural Stones into Vibrant Artworks!

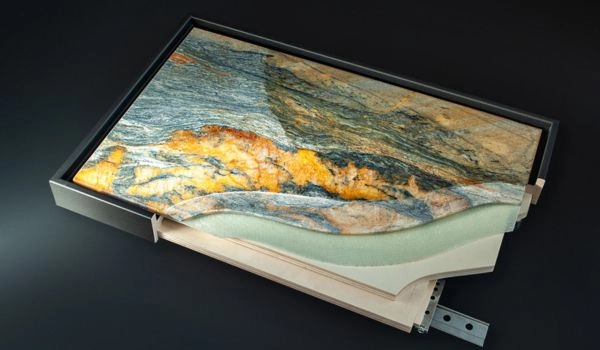

STEINBILD crafts millions of years old natural stones into vibrant artworks, each with its own unique story that transports us to a different era of Earth's history. These extraordinary STEINBILDER are created in our STEINBILD Manufactory. Here, we not only craft the frames but also work with the stone panels, showcasing their exceptional strength and surface texture.

Today, we invite you to delve into the creation process of a STEINBILD and witness its transformation firsthand.

The Process Begins with Cutting

Upon the arrival of the natural stones at our STEINBILD Manufactory, our talented STEINBILD designer, Sarah, takes on the task of determining the perfect cut for each stone.

With her artistic sensibility, she pays attention to the composition, shape, and coloration of the stone. After the individual cutting of the stone, a subsequent color enhancement process brings out the captivating surface texture to its fullest potential.

The Perfect Frame

In the next step, we proceed with crafting the shadow box frames for the STEINBILD. Each STEINBILD is adorned with a premium wooden frame, meticulously handcrafted and refined. This process involves several steps:

.jpg)

Step 1: We begin by cutting the wooden profiles to the correct size.

Step 2: Next, the cut profiles are sanded and brushed. This step is repeated multiple times after each coat of paint, depending on the color.

.jpg)

Step 3: Subsequently, we glue the individual profiles together to form a frame.

Depending on the desired color, the frame is stained, oiled, painted, or laminated. We exclusively use water-based or solvent-free products for this process.

.jpg)

Step 4: After completion, the frames are left to dry for 24 hours in a suspended position.

The Precise Mounting

The last and crucial step is the mounting. This step requires technical precision. Because what may appear simple from the front, is actually complex and technically designed from the back.

"One of the biggest challenges in the development process was neutralizing the expansion coefficient of the millions of years old STEINBILDER in relation to the other components. In this regard, I was able to draw extensively from my 20 years of experience in thin stone and wood processing." Frieder Kattwinkel, Master Carpenter

To ensure maximum load capacity and stability, in addition to the bonding on the shadow box frame, additional components are also screwed to the frame. In our light variation, there are additional components involved, which we will discuss in more detail in a later blog post.

The Final Installation and Certification

After the frame is completed, the installation of the mounting and hanging system takes place. Each STEINBILDis equipped with an integrated mounting system on the back, including wall profile rails, which allow for optimal three-dimensional adjustability and easy installation.

Every STEINBILD is finalized with a unique identification and frame tag, serving to secure ownership rights and distinguishing each art piece as a one-of-a-kind creation. In addition, comprehensive quality assurance is carried out to ensure the highest quality standards for you.

We hope that this post has made it clear to you how much craftsmanship, experience, and expertise are required to create these unique STEINBILDER. Our enthusiasm and joy drive us every day to ensure the highest quality, so that you can enjoy your STEINBILD for a lifetime.

Do you have any wishes or suggestions for our blog?

Feel free to send me an email. I look forward to your feedback!

Best regards,

Sarah from STEINBILD